Blast & Paint Booths

Blast and Paint Booth Services

Looking to have large-scale equipment sand-blasted and painted? The new paint booth and blast booth gracing Handling Specialty’s plant 2 in Hamilton, Ontario is open for business.

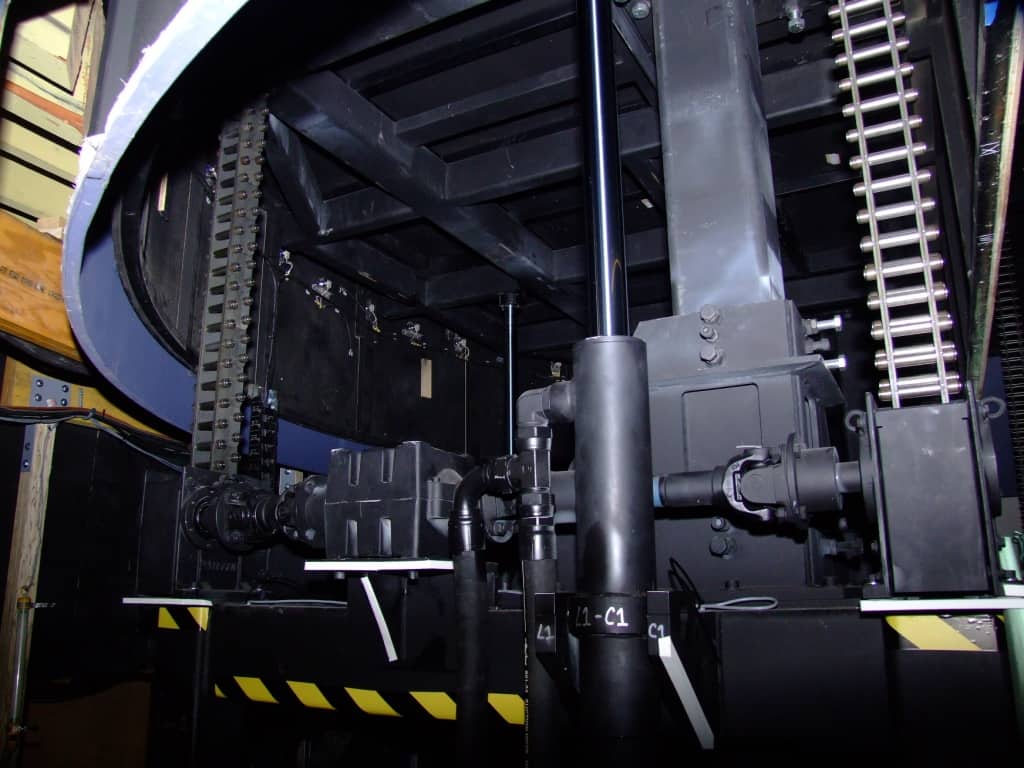

Blast Booth

The new Blast Booth includes an IBT 40’ Long Air Blast Room, IBT 30’ Long Crane Slot Assembly, Powered Door and Structural System, an IBT “Single Auger” Reclaim System, Man Load Bar Grating, HD 1/4” thick Elevator Assembly, an IBT Measured Media System for Improved Economy, PLC Controls, an Axxiom, “Dual Outlet” Blast Pot, 11,200 CFM IBT Cartridge Dust Collector, Secondary/ After Filter Assembly (To return exhaust air back into the building), Exhaust Fan Silencer (To reduce noise from dust collector), Rotary Valve Assembly (To automatically empty dust from dust collector hopper), and a Pressure Relief Panel on Dust Collector. Our blast booth is capable of accepting weldments up to 12 feet wide.

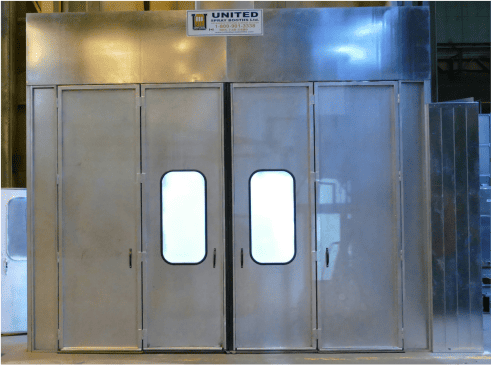

Paint Booth

The Industrial Pressurized Semi-Down Draft Spray Paint Booth with external dimensions of 18’W x 49’L x 11’H allows for product parts to undergo the paint process on-site up to dimensions of 16’W x 45’L x 11’H. The paint booth includes a galvanized Finish, exhaust system with LED lights, one air replacement unit, Spray gun Interlock kits with airflow manometer, Integrated electrical control panels with time relay and digital temperature controller, Variable electronic speed control system for spray booth exhaust fan, Reinforced exhaust filter chamber with a 30’ exhaust stack and a Fire protection dry chemical sprinkler system. Our paint booth doors accept weldments up to 13 feet wide.

Paint Booth Services

The Industrial Pressurized Semi-Down Draft Spray Paint Booth with external dimensions of 18’W x 49’L x 11’H allows for product parts to undergo the paint process on-site up to dimensions of 16’W x 45’L x 11’H. The paint booth includes a galvanized Finish, exhaust system with LED lights, one air replacement unit, Spray gun Interlock kits with airflow manometer, Integrated electrical control panels with time relay and digital temperature controller, Variable electronic speed control system for spray booth exhaust fan, Reinforced exhaust filter chamber with a 30’ exhaust stack and a Fire protection dry chemical sprinkler system.

Our paint booth doors accept weldments up to 13’ wide.

The booth was provided by United Paint Booths with an Air/Air assist spray paint system by Graco. NACE-certified Level 2 Inspector on-site with quick access to Level 3 Inspectors. The paint booth offers paint, coatings and finishings. An SSPC member and Trainer for their Train the Painter program is also available on-site for questions and information sharing. The climate-controlled workspace means environmental conditions within the booth are optimal for a perfect finish every time.

Quality documentation, including NACE Inspection, is created with each paint project, and it is available upon request. Click for a list of our Handling Standard colours. Custom and other colours are available upon request.

Blast Booth Services

The new Blast Booth includes an IBT 40’ Long Air Blast Room, IBT 30’ Long Crane Slot Assembly, Powered Door and Structural System, an IBT “Single Auger” Reclaim System, Man Load Bar Grating, HD 1/4” thick Elevator Assembly, an IBT Measured Media System for Improved Economy, PLC Controls, an Axxiom, “Dual Outlet” Blast Pot, 11,200 CFM IBT Cartridge Dust Collector, Secondary/ After Filter Assembly (To return exhaust air back into the building), Exhaust Fan Silencer (To reduce noise from dust collector), Rotary Valve Assembly (To automatically empty dust from dust collector hopper), and a Pressure Relief Panel on Dust Collector.

Our blast booth is capable of accepting weldments up to 12 feet wide.

Paint & Blast Booth Gallery

To discuss all Paint and Blast Booth services please