Handling Specialty's Facilities

Handling Specialty's Facilities

Our facilities include more than one building and many departments to design/build your next custom material handling system.

Call us at 905-945-9661 or contact our sales team.

219 South Service Road West, Grimsby, Ontario, Canada.

Established 1963 – 40,000 square feet

- Engineering

- Sales

- Parts & Services

- Quality Assurance

- Project Management

- Purchasing

- Operations

- Accounting

- Marketing

- Conference Rooms

- Shipping/Receiving

- Manufacturing

- Weld cells

- Paint booth – 14’-0” wide by 25’-0” long

- 4 x 5 ton bridge cranes, 7 x 0.5 ton jib cranes

1632 Burlington Street, Hamilton, Ontario, Canada.

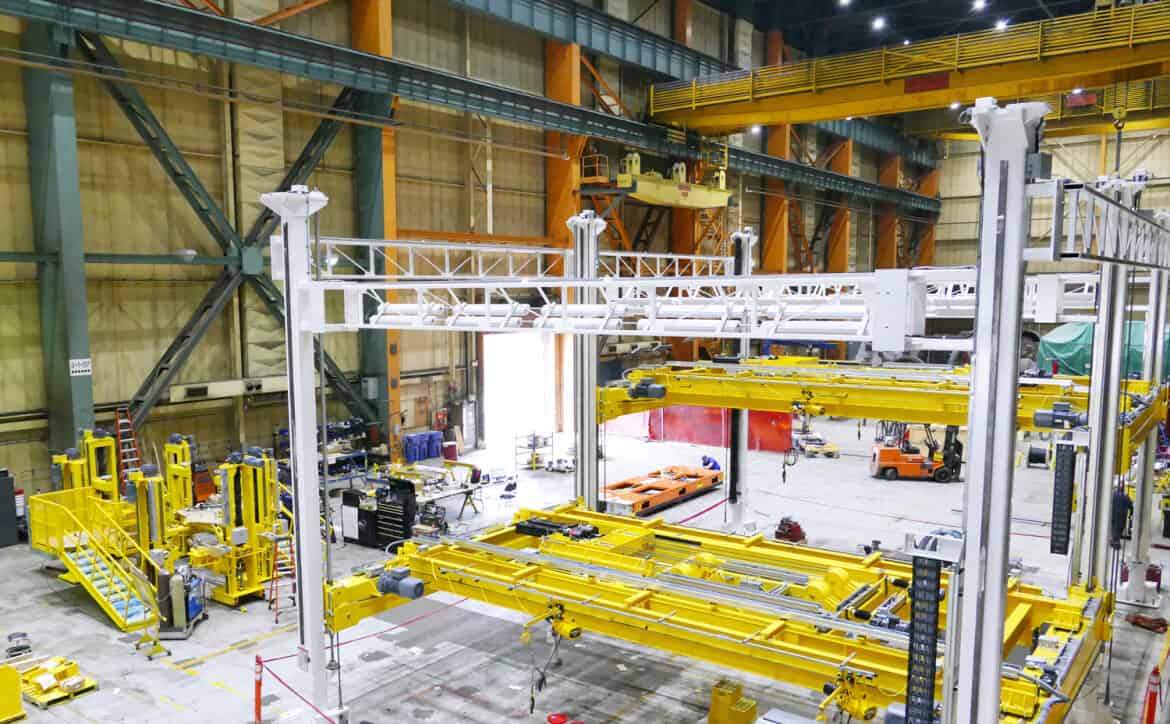

Established 2008 – 100,000 square feet

- Blast booth – 45’ long, 11’ high and 16’ width

- Paint booth – 45’ long, 11’ high and 16’ width

- Manufacturing with 105′ ceilings

- Quality Assurance

- Operations

- Project Management

- Conference Rooms

- Shipping/Receiving: 6, 21′ roll-up bay doors

- Heavy-duty Cranes: 180-ton main hoist crane with one 20 ton auxiliary hoist crane, 20-ton main hoist bridge, 10.5-ton bridge, 10-ton bridge crane, 2 x 5-ton bridge cranes, 2 x 1-ton jib cranes (Massive capability for indoor rigging tasks with lifting heights up to 70 feet and 160 tons)

- 18 weld cells

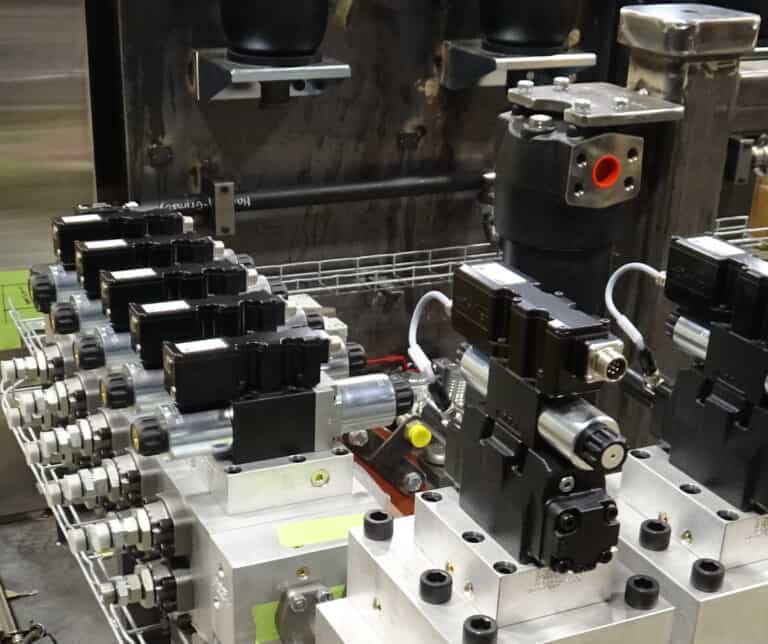

- Hydraulic VMI work center

- Power and Control VMI and panel building center

Handling specialty currently operates out of two facilities. The first is our head office and manufacturing facility (Plant 1), with 40,000 sq. feet at 219 South Service Road in Grimsby, Ontario, and 100,000 sq. ft at Plant 2, at 1632 Burlington Street in Hamilton, Ontario. The Grimsby facility, known as Plant 1, also houses the head office. The Hamilton facility (Plant 2) manages large-scale projects and those requiring large open test areas. In contrast, the Grimsby facility handles smaller-scale projects, pre-assemblies and R & D. With state-of-the-art manufacturing facilities and highly-trained personnel, Handling Specialty will assess, design, manufacture, and install custom material handling equipment specific to your applications.

The physical assets of our plant 2 in Hamilton offer 105′ ceilings, spans between columns for large horizontal builds and test track layouts, drive-in trucking for safe, efficient load-in/out and tarping or overseas container prep. Plant 2 also includes our large-scale Paint booth and new Blast booth operations, where all our equipment is given professional, industrial-strength coats of high-quality paint before shipping to the customer. We also offer blast & paint services to other clients in greater Hamilton.

Plant 1 houses our sales, engineering, quality control, parts and service, project managers, marketing, manufacturing, and a smaller-scale paint shop.

With less than 20 kilometres separating the two facilities, Handling’s personnel have easy access to both, allowing for transfers and visits from the production, engineering and management staff when necessary.

Handling Specialty sells equipment all over the world, and so are proficient in the preparation of overseas shipping procedures. We ship from both Plant 1 and Plant 2.

Gallery