Heavy-Duty Scissor Lifts for Material Handling

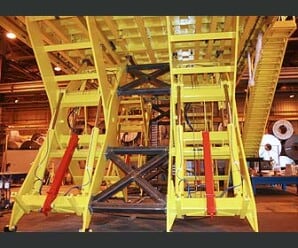

A heavy-duty scissor lift is a mechanical lifting device built for the specific purpose of raising and lowering products and or people to a desired height. As with all custom-engineered heavy-duty scissor lifts, they can be offered in single-scissor, double-scissor wide, double-scissor long, or quad-scissor double wide/double-long configurations. Lifting capacities trend toward tons rather than lbs.

As with all material handling equipment, heavy-duty scissor lifts come with an array of custom specifications, including lift capacities, dimensions, maximum height, lowered heights, horsepower, actuation and safety measures. Handling Specialty specializes in custom scissor lifts and has built many models over the years to meet the application requirements of our customers. The scissor lift is an exceptionally diverse piece of equipment allowing for multiple uses within multiple industries, including power-gen, automotive, aerospace, advanced manufacturing, process manufacturing, steel foundries, transportation, and even entertainment stage lifts. Heavy-duty scissor lifts are found in every industry where precise positioning of equipment and personnel is needed.

A scissor lift can also be found secured to a guided vehicle as it moves through the assembly line. In this application, the lift is pre-programmed to raise and lower to specific heights allowing for precise positioning at each work cell. All heavy-duty scissor lifts include an externally-mounted power unit and can include mounted controls or a handheld pendant design.

A heavy-duty scissor lift must be designed with robust components and multiple safety features. The actuation of the lift must support the weight of a customer’s product and be engineered to work flawlessly in demanding environments where multiple cycles per hour or day will test its resiliency.

Handling Specialty can assist in every step of the process by visiting your facility, engineering the right design for your applications, and supporting your material handling equipment throughout its life. For more on our robust solutions, contact our technical sales department.