Understanding the Differences Between the AGV and MGV

Understanding the differences between the AGV and MGV, in large part, depends on the vehicle’s intelligence. Does the guided vehicle require an operator to maneuver it through its paces, or does it move along a predetermined course via programming?

Main Difference of the AGV and MGV

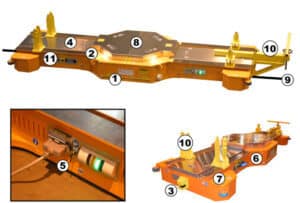

An automated guided vehicle and a manually guided vehicle can perform the same duties when moving and positioning a product or part for assembly, manufacturing, or maintenance & repair operations. Both guided vehicles can be outfitted with custom tools, rotating table tops, scissor lifts, and tilting tables and be customized in shape and size. Both an AGV and MGV can be engineered to move any weight capacity a client requires.

That leaves the intelligence factor as the main descriptor that separates an AGV from an MGV. Intelligent AGV systems offer programming opportunities to follow a set path, stop and start at work cells, and position product to predetermined heights for the technician to work ergonomically. An AGV system injects safety and efficiency into any operation.

An MGV also offers efficiency and safety in your factory or plant with the same safety precautions, such as audible alarms, flashing lights, and motion sensors. The difference between an AGV to an MGV is that an MGV does not drive itself through the line. An operator controls the MGVs movements via a hand-held controller either remotely or wired to the manually guided vehicle.

Both AGV and MGV are designed to your industry’s specific application requirements. Heavy-duty frames engineered to handle heavy loads and multiple cycles per day are built into the guided vehicles. Robust, modular, DC-powered guided vehicles feature a drive motor with an integral brake for smoother starting and stopping.

Either an AGV or an MGV can be fitted with multi-directional steering. Forward/backward, side-to-side, diagonal, and zero-point turning are all available to both models of guided vehicles.

Convert my MGV to an AGV

Adaptable to accommodate production growth, the manually guided vehicle can be upgraded into an automatic guided vehicle without significant infrastructure change or investment. Once an MGV is employed, new tech can be integrated, and the MGV becomes an AGV.

Do AGVs and MGVs perform the same work?

Yes, AGVs and MGVs perform the same work in multiple industries. The question put to our clients is whether they want their guided vehicles to be automated or manually driven. Automation offers a hands-off option where the autonomous guided vehicle drives itself through processes as determined by the client for as many cycles as is required. MGVs operate the same way but require an operator to drive them. Otherwise, both the AGV and MGV perform exactly the same tasks in an assembly, manufacturing and MRO scenario.

IIoT for AGV and MGVs

The Industry Internet of Things is another option to consider for both your AGV and MGV. IIoT allows your guided vehicles to talk to each other and to a master control panel alerting the client of parts wear and tear, battery life, and other integral system notifications. This preemptive information can drastically decrease downtime in your facility, further increasing your efficiency and safety.

AGV or MGV Orders

When looking to employ a custom AGV or MGV, do your research on design/build firms that can draw from years of experience and include multiple case studies like Handling Specialty. Contact our experienced technical sales team today for a quote on an AGV or MGV for your operations.