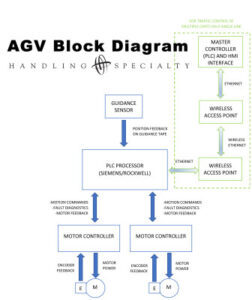

An AGV Block Diagram offers a visual schematic of the general arrangement of the parts and components of the complex system that guides the automated guided vehicle.

An automatic guided vehicles navigation and steering controls feed information to the AGV traffic control system designed with multiple safety features which offer exceptional traffic control within a facility through collision-avoidance capabilities.

A central control fed by a wireless ethernet connection allows operations the ability to monitor all AGVs on the line while IIoT 4.0 technology onboard the AGVs reports any issues with the individual units.

AGV Guidance Sensors can come in several forms, such as Magnetic tape, laser, vision and natural navigation. These are the technologies most popularly used in modern AGVs, depending on the specific application requirements.

PLC for an AGV is a programmable logic controller designed to be used in the material handling industry to assist in the guidance of the automated guided vehicle.

An Autonomous Guided Vehicle Motor Controller allows each wheel or wheelset on the AGV to react to what the guidance system is relaying. These motors are often brushless DC motors and, when combined, are capable of moving the AGV in multiple directions and even performing zero-radius turns, crabbing and diagonal movements.

The AGV Master Control Panel is outfitted with an HMI screen offering digital outputs on each of the AGV’s positions and health. It is fed information from each unit via wireless ethernet connections. An operator can alter an AGVs movements from this panel and ask it to dock at a charging station or maintenance port.

An autonomous guided vehicle block diagram is an excellent opportunity to break down the components and processes and clearly lay out the basic structure. Handling Specialty is a custom design/build firm that creates turnkey AGV systems for multiple industries in the assembly and manufacturing of large-scale products. Serving the aerospace, automotive, advanced manufacturing, power generation, steel, process, and rail and transportation industries.

For inquiries on your AGV system, contact our technical sales.