Overview

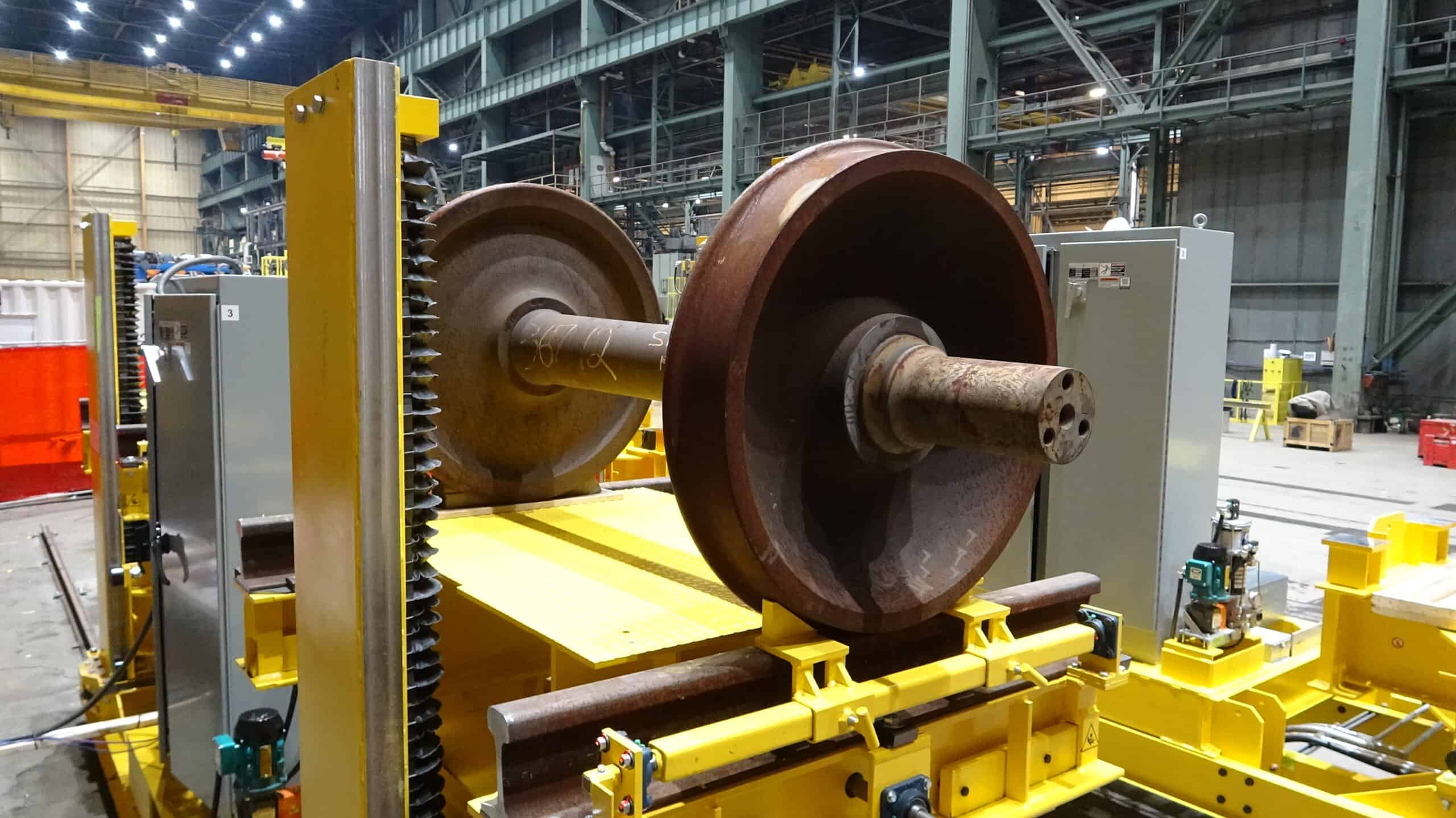

The Double Drop Table is a fully engineered mobile hoist system that will facilitate the replacement of an existing rail car wheelset with a new wheelset.

The Double Drop Tables traverse on a set of rails laid perpendicularly and below the elevation of the rail car service tracks in a trench of prescribed depth. Two independently functioning twenty (20) metric ton hoist systems are located at either end of the Drop Table, both of which can contain, at various stages of the operation, either the existing wheelset being replaced or the new wheelset being installed. Ultimately, the Double Drop Table has been designed to decrease wheelset change-out cycle times by making the new wheelset promptly available after the existing wheelset has been removed.

Typically, one (1) new wheelset is loaded at a Wheelset Loading Station onto the Double Drop Table hoist that contains a Service Top. Upon command, the Drop Table traverses in the lower trench and is designed to position itself repeatedly and accurately at a Wheelset Change Station, an area in the facility service track that functions as the location where the wheelsets are removed and replaced.

Features

- 20 Ton Double Drop Tables.

- Four (4) Service Tops.

- One (1) set of Locking Bar Pockets.

- HMI consoles.

- Limit switches.

- Safety light.