Overview

A DC Battery Powered Ladle Lift removes the cords that can be pinched and severed, making the process of raising and lowering the technician safer.

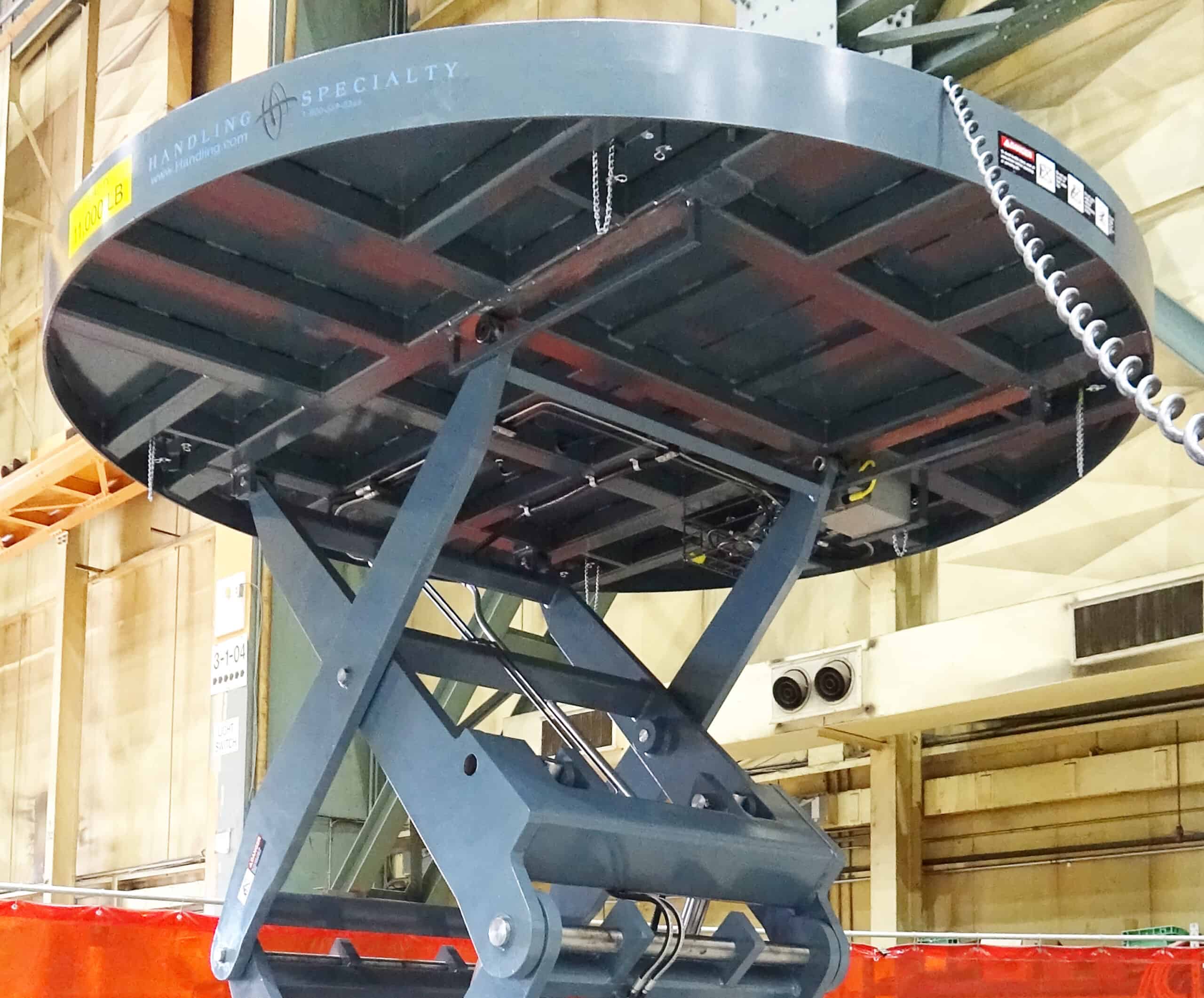

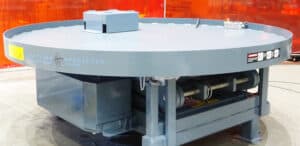

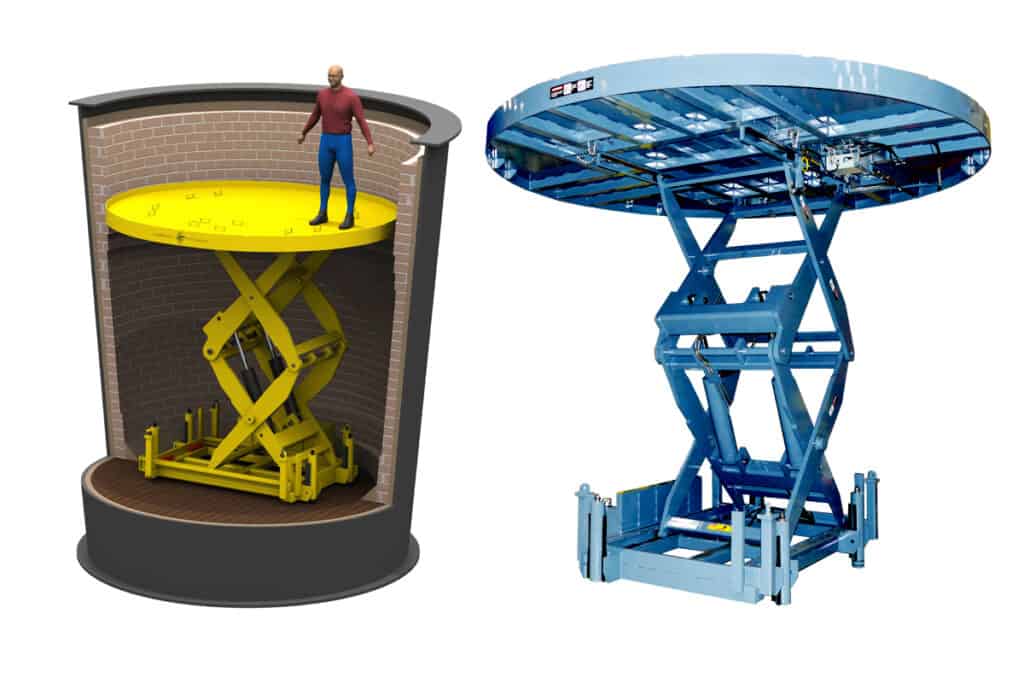

Since refractory firebrick in pour ladles requires continual replacement, the ladle lift replaces traditional scaffolding used in the re-bricking job. The lift is loaded into the ladle using a crane, its portable design engineered to sit in the base of the ladle where it rises and lowers with the Firebricks and the technician. The ladle lift can be moved to the next ladle requiring re-bricking in quick succession. These two-stage scissor lifts are designed to withstand harsh melt shop environments.

DC Battery IIoT Technology: With Bluetooth built-in, an APP on your mobile phone or tablet will alert you to battery charge levels and other important information, employing the Industrial Internet of Things (IIoT) technology. One bad cell or one bad battery can destroy a large, expensive battery bank. When batteries are connected in series, a timely warning can be generated by measuring the midpoint voltage.

Other features of the Smart Bluetooth APP

- Battery voltage, current, power, ampere-hours consumed and state of charge.

- Remaining time at the current rate of discharge.

- Programmable visual and audible alarm.

- Programmable relay to turn off non-critical loads or to run a generator when needed.

- 500 Amp quick connect shunt and connection kit.

- Shunt selection capability up to 10,000 Amps.

- VE.Direct communication port.

- Stores a wide range of historical events, which can be used to evaluate usage patterns and battery health.

- Wide input voltage range: 6.5 – 70 V.

- High current measurement resolution: 10 mA (0.01 A).

- Additional input to measure voltage (of a second battery), temperature or midpoint voltage, and corresponding alarm and relay settings.

Features

- 460V/3PH/60Hz or 24VDC with DC option purchased.

- The ladle lift is equipped with a fully automatic 110VAC electric charger to charge the onboard 24VDC battery system.

- While the charging cord is plugged in, the raise and lower functions are disabled.

- Handheld pendant, 3 Buttons – Up/Down/E-Stop & Foot pedal with a heavy-duty cover.

- Up/Down travel limit switch.

- 2 hydraulic cylinders.

- Provided with a structurally engineered checker plate lifting platform.

- Access panels to lifting shackles, manual lowering valve, storage for operator push button pendant, and primary voltage interface point.

- “Armored” HPU and shackles for a four-point lift.