Overview

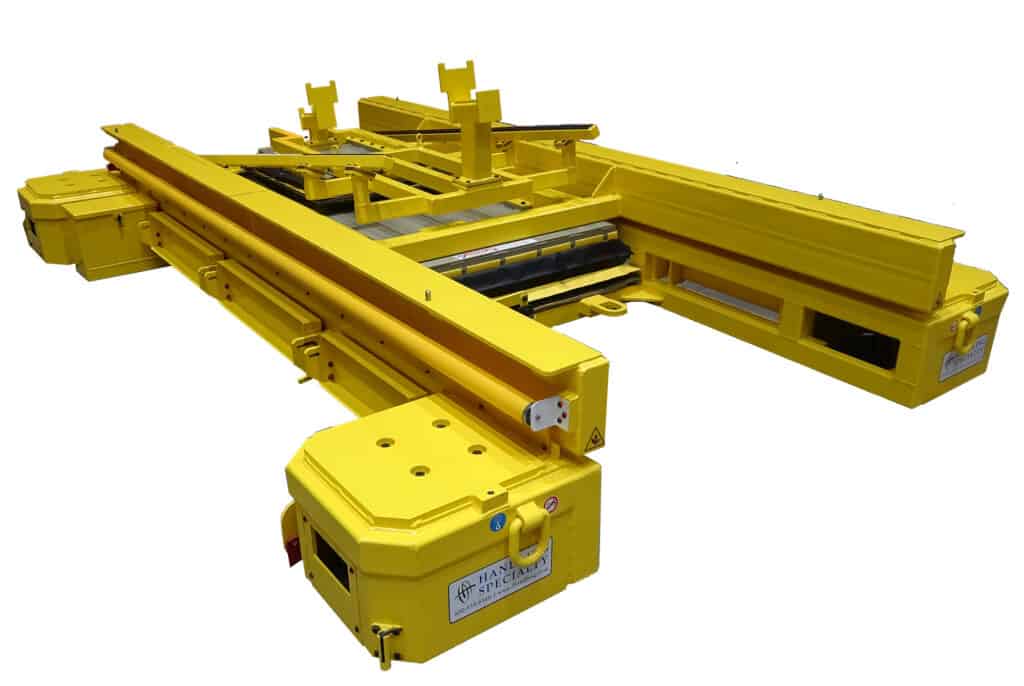

Handling Specialty pioneered a unique conveyor platform system at Saturn’s Spring Hill, Tennessee, assembly plant. Referred to as a “skillet,” these high-cycle electro-mechanical custom scissor lifts were incorporated into more than 200 platforms. On these platforms, workers could be found riding alongside vehicles. As each car came down the line, the worker adjusted the height of the vehicle by foot pedals to suit their ergonomic position. An operator-controlled foot switch activated the lift, which employed an electro-mechanical drive combined with cam-style scissor geometry. This was successful in achieving constant-speed lifting with very low power requirements.

Features

- They are also known as skillet lifts.

- Completely customizable.

- Mechanical actuation for level, steady lifting with zero creep.

- Adjustable to any height.

- High-cycle scissor lifts called “skillets” are incorporated into platforms for an ergonomically correct automobile assembly line.

- Constant-speed lifting with low power requirements.

- The height of the vehicle is adjusted by an operator-controlled foot switch to meet each worker’s unique needs.