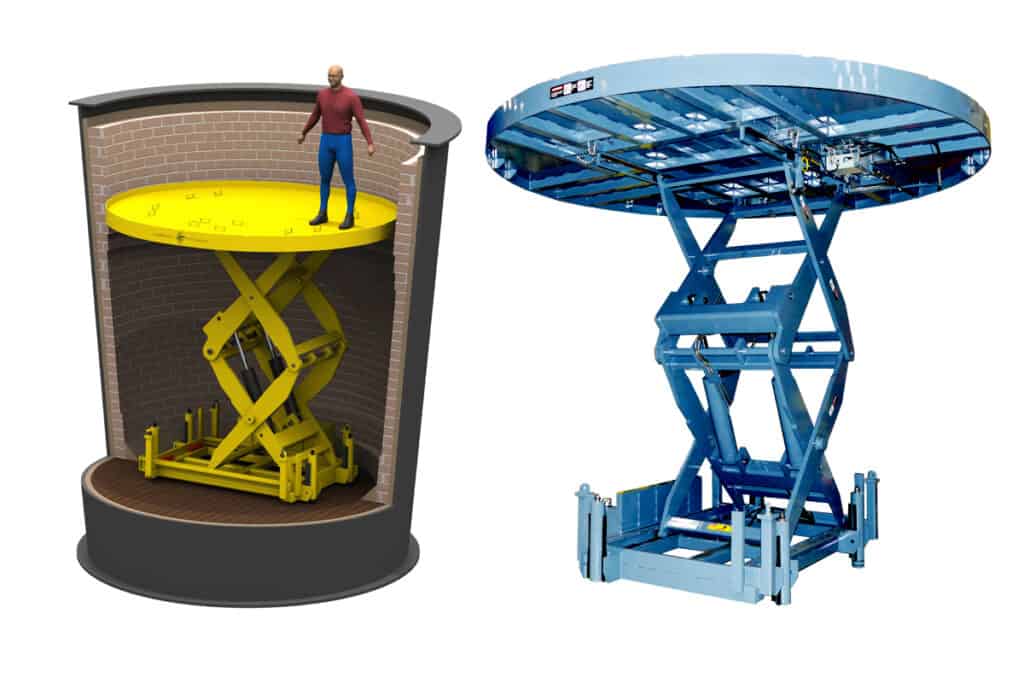

Overview

This Custom Scissor Lift with Rotator will be used to stack zinc plates in a smelting process. Built with heavy-duty steel to withstand the rigours of a smelting operation, the lifts include the rotator on top of the platform. These lifts will run 129 cycles/hour, 24 hours a day, 310 days a year.

Features

- The scissor lift is designed to be powered up and gravity down and to work with the purchaser’s existing HPU at 900 psi.

- Includes proximity sensors for “fully down” and “rotate height” sensing, wired to the Junction Box on the base of the lift

- Velocity fuses are installed at the base of each cylinder. Cylinders plumbed to manifold on base.

- Includes chemical-resistant bellows around the lift. This requires 3″ of free space around the lift to clear bellows.

- Includes maintenance blocks.

- HPU by the purchaser, lift, and lower speeds dependent on HPU performance and controls.

- Rotary Table is supported by a slewing ring with external teeth, driven by a hydraulic motor plumbed to the manifold on the base.

- Includes idler gear with rotary encoder for position feedback to purchaser’s controls.

- The encoder is wired to JB on base.

- A grease fitting is provided on the side of the platform for slewing ring lubrication.