Safety is always an important consideration when designing a product to help others do their jobs more efficiently. Ergonomics should also be considered when making a decision on a piece of equipment being designed to assist employees in the manufacturing industry.

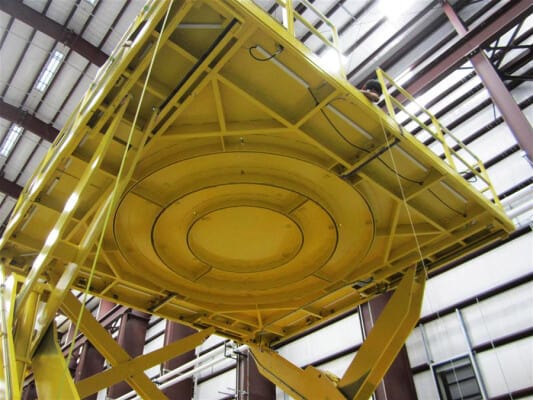

Handling Specialty has been designing, building and supporting products like multi-stage turbine lifts for decades, and has engineered lifts which amplify safety and ergonomics. In particular, the at-grade, or below-ground level, multi-stage scissor lift allows the employees to remain on the ground as the turbine raises and lowers at the worker’s level, rather than the employee raising and lowering on a platform to meet the different segments of the turbine. The ground-level lift eliminates staircases and heights associated with traditional above-ground turbine lifts, reducing the possibility of accidents, including falling from a great height. The platform featured below includes two round removable plates, which can be manufactured in a variety of sizes to fit any turbine diameter.

This scenario is not always ideal for the factory’s architecture or the manufacturer’s needs, but having your personnel remain on the ground while they build or maintain massive turbines for the Gas, Oil, and Energy industries does offer increased safety and ergonomics which in turn, can lower costs due to employee injury, and raise morale in the company.

Even with safety features like safety lock-up bars to hold the lift in a raised position for regular maintenance and hydraulic cylinders equipped with velocity fuses to provide the rate of descent protection, the above-ground turbine scissor lift is not as safe as the below-ground version because operator complacency is a danger in every instance where heights are involved.

In order to increase your peace of mind, a below-ground lift is an ideal solution for turbine manufacturing applications. For more on these custom or pre-engineered versions of a turbine lift, please visit our website, or call directly.

Above-ground scissor lift is featured here.